How SMEs Can Power the Global Race to Fusion Commercialization

For decades, fusion has been portrayed as a field dominated by national labs, billion-dollar reactors, and massive engineering challenges. Yet a quiet shift is reshaping this narrative: small and medium-sized enterprises (SMEs) are emerging as the backbone of a rapidly growing global fusion ecosystem.As the world urgently seeks secure, clean, and limitless energy solutions, today’s fusion landscape—from private startups in the U.S. to public–private partnerships in Europe and Asia—is increasingly relying on specialized suppliers, ultra-precise manufacturers, and innovation-driven small companies to solve problems that large institutions cannot handle alone. As fusion moves from scientific experiment toward a commercial reality, SMEs are proving indispensable. Fusion may be big science, but its future depends on small players.

The Missing Link in the Fusion Supply Chain

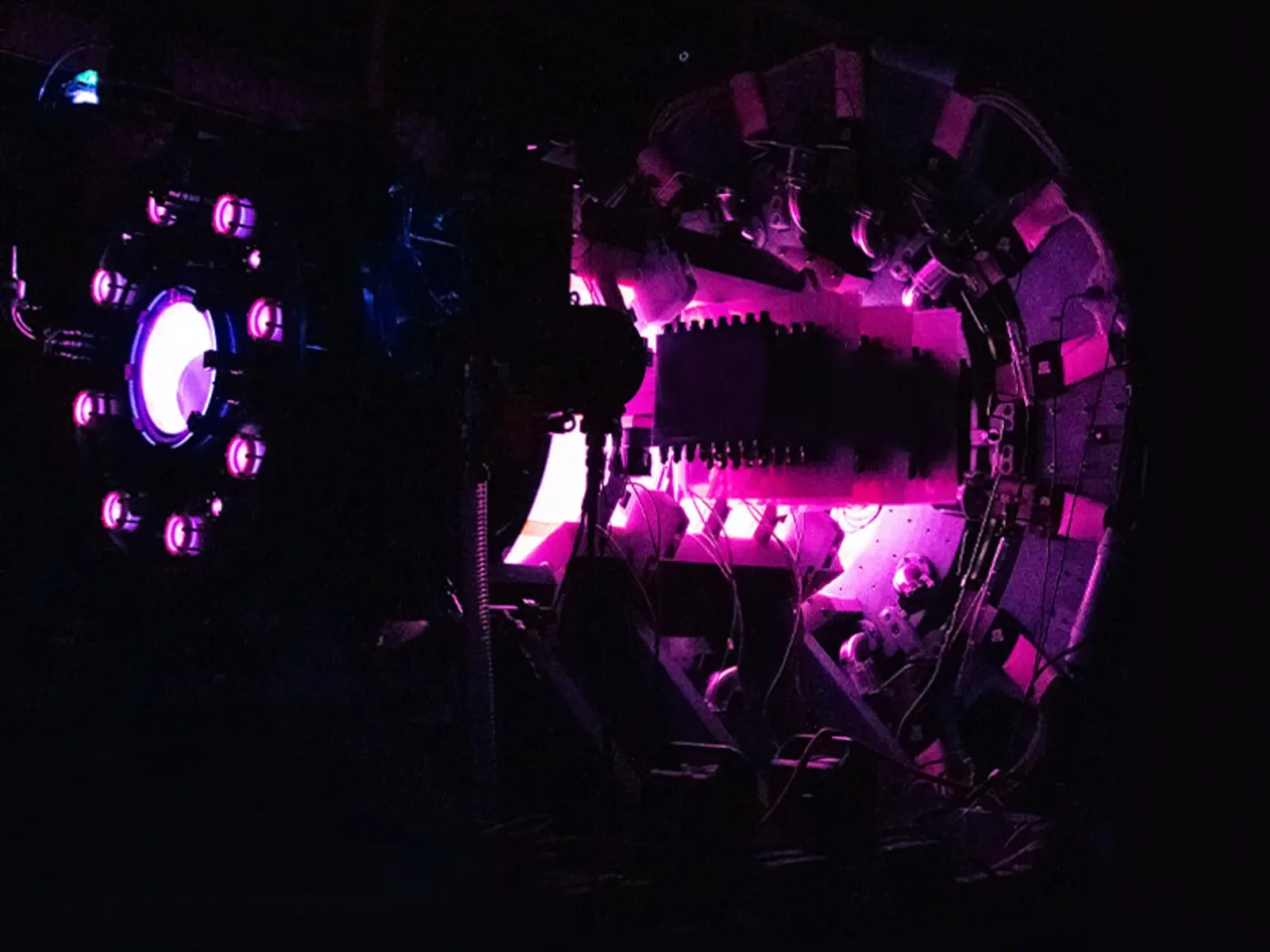

Fusion projects require thousands of highly specialized components — from cryogenic systems and superconducting cables to advanced robotics and radiation-resistant materials. No single large company or national laboratory can produce all of these internally, which opens a vital space for SMEs. These smaller firms excel in areas where hyper-specialization is needed. Many of them have mastered niche capabilities such as high-performance ceramics, ultra-precise machining, advanced diagnostic tools, or custom power electronics.

Their ability to innovate quickly and develop tailored solutions makes them invaluable partners to fusion developers. Unlike larger contractors that often move slowly, SMEs are willing to experiment, co-design, and iterate alongside fusion teams. They also strengthen local industrial ecosystems by anchoring regional manufacturing capabilities and reducing reliance on distant or monopolized suppliers.

Crucially, many of these firms bring cross-industry expertise, transferring proven, high-reliability techniques from aerospace, semiconductor, or medical-device sectors into fusion. This cross-pollination is invaluable, enriching the fusion space with new techniques and technologies while de-risking development. Big fusion institutions like Fusion for Energy (F4E) actively invest in engaging with SMEs because they know the resilience of the fusion supply chain depends on them.

SMEs as The Industrial Backbone

Fusion’s momentum is no longer driven only by governments and research institutions. While international agreements and scientific collaboration set the direction, the actual building of fusion systems depends on industrial capabilities, especially the SMEs. As more countries accelerate their fusion programmes, demand for high-precision components, advanced materials, robotics, digital tools, and engineering services is increasing faster than any single national supply chain can support. This creates opportunities for SMEs worldwide to supply specialized products and expertise, regardless of whether their country hosts a fusion reactor or national programme.

In the UK, for example, over 75% of fusion industry suppliers are SMEs, and the same pattern is emerging across Europe and Asia. The ITER project itself is built by hundreds of SMEs across multiple continents. The fusion economy is already global, and SMEs provide the connective tissue that keeps it running. This transformation proves that global collaboration in fusion is now an industrial story, where SMEs from across continents collectively form the robust, multi-national capabilities required to turn fusion into a viable, scalable energy source.

SMEs Accelerate Commercialization Through Agility

Fusion developers need supply chains capable of keeping pace with fast-moving research and design changes. Unlike large industrial suppliers that require long timelines and rigid processes, SMEs can adapt quickly to evolving requirements. Their agility enables rapid prototyping, design iteration, and custom fabrication. All of which shorten the development cycle from prototype to pilot plant to fully operational power plant.

Many studies show that SMEs actively accelerate innovation by becoming deeply embedded partners in R&D efforts. They work alongside fusion teams, respond immediately to new engineering challenges, and provide specialized expertise that cannot be found elsewhere. This agility becomes a competitive advantage for the entire fusion industry, leading to faster breakthroughs and significantly shortening the time-to-market for commercial technology, which is vital for attracting continuous private investment.

SMEs Make Fusion Possible

Fusion is one of humanity’s most ambitious technological undertakings. Its success will not come from a single laboratory, company, or nation. It will come from a distributed network of highly specialized contributors which many of whom are small and medium-sized enterprises.

A ceramics maker in Japan, a diagnostics startup in Singapore, a precision engineering firm in Malaysia, a cryogenics SME in Germany, or a materials innovator in Canada can each provide something essential. These firms are not just suppliers; they collectively form the industrial foundation that makes fusion possible.

As the world races toward fusion energy, SMEs will be the quiet force powering its momentum, turning big science into a scalable global industry.